Wecon Systems carries sanitary conveyors from Dorner, the leading manufacturer of precision conveyors. Designed to confidently and reliably meet the needs of the bakery, confection, snack and prepared foods, and protein markets. Dorner’s sanitary conveyors are available in various sizes, with many options and features.

Dorner’s AquaGard and AquaPruf lines of stainless steel, sanitary conveyors are the ideal choice for food industry applications. These innovative conveyors feature a hygienic design for fast and effective cleaning, whether an occasional wipe down or a frequent high-pressure wash down is required.

A Reliable Lineup

AquaGard and AquaPruf conveyors are available in flat belt and cleated belt designs, as well as z-configurations with angles up to 60 degrees, and curved designs from 45 to 180 degrees. Both are constructed of TIG welded stainless steel with belt and plastic chain. All materials used are FDA approved.

The AquaGard models are ideal for sanitary applications that require a low pressure wash of up to 100 psi, and mild chemical resistance. These conveyors can also be BISSC certified.

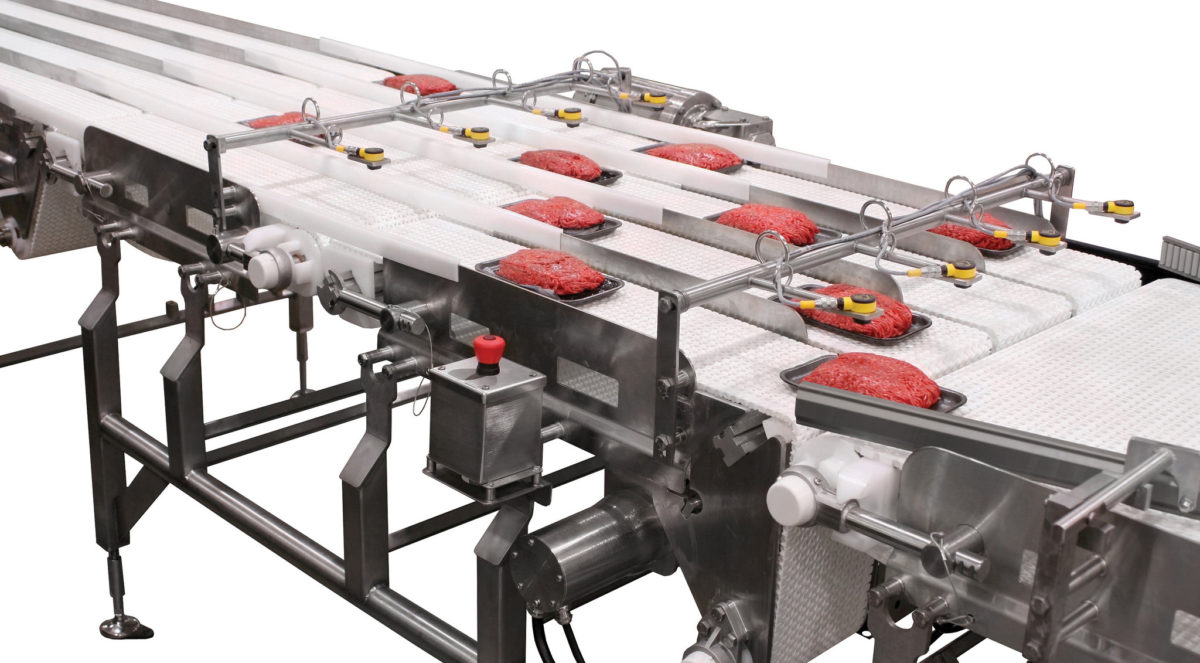

AquaPruf conveyors, on the other hand, are suitable for both wash-down and sanitary environments. They are designed for high-pressure wash downs up to 1,500 psi and offer chemical resistance. These conveyors are also available to meet AMI standards, and with USDA red meat and poultry accepted equipment certification.

1x Series

The 1x Series is designed for small part handling and transfers where space is a premium. It is only available with a flat belt and aluminum frame; however, this series comes in widths up to 10 inches, can carry loads up to 15 lbs, and moves at speeds up to 80 feet per minute.

2x Series

The 2x Series is engineered for small to medium-sized parts, precision applications and flexible layouts. These conveyors are available with flat, cleated or modular belts, as well as a Precision Move timing belt and SmartFlex flexible chain. Constructed with an aluminum frame, this series comes in widths up to 24 inches, can carry loads up to 200 lbs, and can move at speeds up to 400 feet per minute. The 2x Series offers more flexibility, as it is able to curve, incline or decline.

3x Series

This line is designed for medium-sized to heavy parts, precision applications, bulk handling and flexible layouts. It’s available with the same belt and chain options as the 2x Series; however, these conveyors can carry much larger loads, faster. Constructed with an aluminum frame, the 3X Series comes in widths up to 60 inches, can carry loads up to 1,000 lbs, and can move at speeds up to 600 feet per minute. Plus, it is able to curve and can work with Z-frame elevators.

7x Series

Constructed of stainless steel, the 7x Series is engineered for small to heavy products that require varying levels of sanitary design and flexible layouts. They are AquaPruf and AquaGuard models, which means they are designed to withstand complete washdowns. This family is available with flat, cleated or modular belts, as well as a flexible chain. It comes in widths up to 60 inches, can carry loads up to 750 lbs, and can move at speeds up to 400 feet per minute. In addition, it is able to curve and can work with Z-frame elevators.

A Reliable Solutions Provider

Dorner’s lineup of sanitary conveyors is designed to meet the precise requirements of the bakery, confection, snack and prepared foods and protein markets with confidence and reliability. Wecon can provide these conveyors to customers with that same confidence and reliability thanks to its expertise in conveyor system design and installation, from single conveyor units to multimillion-dollar systems. Working with Wecon as a solutions provider gives customers access to the company’s seasoned application specialists, project managers, designers and programmers, and its range of services — concept and design, needs analysis, systems integration, turnkey solutions, manufacturing and fabricating, preventative maintenance, service and installation.

This means developing the correct concept, selecting the right equipment and professionally installing it, while remaining within budget and on schedule.

To learn more about these Dorner sanitary conveyors, contact Wecon Systems!